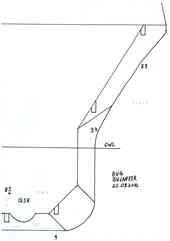

Supply Vessel Pacific Buccaneer

Page 2

|

|

|

|

As

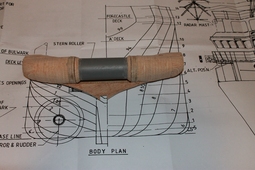

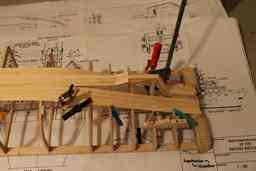

soon as all ribs were cut and the bow and stern post were manufactured

it was possible to compose the skeleton of the body for the first time.

For the strengthening in the longitudinal direction stringer were added. |

|

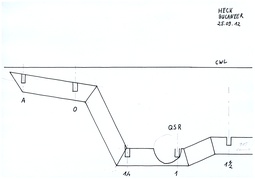

Before

the skeleton could be glued

it was necessary to manufacture the stern role and integrate it into

the bulkhead "A". The shape of the stern was formed with

several circular beech discs which were glued together so

that they formed a cylinder. A problem in this context occured due the

different views in the drawing show various measures. |

|

|

The pictures beside display the construction progress until 01/11/2012. The next tasks were the integration of drive shafts as well as the stern post and the manufacturing of the helm. |

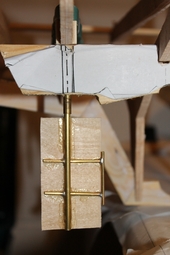

16/11/2012: The

supplier is equipped with so called "Becker Rudders" wich shall improve

the maneuverability of the ship.

On principle "Becker-Rudders" consist of a bigger rudder blade onto

which a movable fin is connected. A crank of lever which is connected

to the body of the ship forces the fin to turn twice the angle of the

bigger rudder blade.

|

|

The skeleton of the helm is given by a construction of soldered brass pipes which are covered with ply wood as visible in the pictures displayed beside. |

|

|

The fotos on the left side show the movable fin and the lever crank which is pivoted in the the hull. |

|

Drive shaft with screw and helm complete. But the "Cort-Nozzles" are still missing. |

|

|

Stand 01/12/2012: In order to fix the planks it occured reasonable to pierce a slot into the bow. The planks consist of pine wood with a thickness of 2 mm. For the areas of the hull with a strong bending planks of 5 mm breadth were applied. The large flat areas were planked with wood of 10 mm breadth. |

The

rails are 1.0 m long and therefore shorter than the ship. So it was

necessary to prolonge the strips. During the construction it was obeyed

that the links were to be positioned right over the bulkheads.

|

|

Progress till 16/12/2012:

Since the planking of the hull obviously would take a while I meanwhile

started with the construction of the "Kort-Nozzles". The

nozzles

should be produced by deep drawing, what provided a

completely

new experience to me. Initially the negative was shaped out of pine wood. In the next step a ploystyrene sheet was fixed between two ply-wood sheets. |

After

warming up the plastic sheet with a hot air gun the negative form was

pressed into the polystyrene. The only difficulty of this technique

consists in warming up the plastics homogenously. Inhomogen

temperatures result in uneven wall thickness and that means

the only reasonablel usage of the

created item is to through it into the liter box :) ...

On principle

"Kort-Nozzlels" unify three advantages:

They focus the jet of water, what increases the bollard pull. They reduce vortexes at the ends of the propeller blades, what avoids disturbing the ground in swallow waters. They protect marine propeller in case of touching the sea bed.

The purpose of the bilge keels is to reduce the roling of the ship.

Since the drawings do not show the keels I was forced to determine the dimensions and possition from fotographs of other models and from the original ship. For the construction three pine wood ledgers 5 x 5 mm and 1 strip 10 x 2 mm have been applied.

|

|